Do you own a saw and want to ensure you’re using the right guard? In this blog post, we’ll be discussing Type 1 vs Type 27 guards so that you can confidently choose the one best suited for your saw.

Whether you’re slicing through metal or just cutting into lumber, it’s essential to understand the factors involved in ensuring your guard fits correctly. You will know different types of guards and everything they offer, no matter what kind of job you need to do here.

Grinding, an essential part of metal fabrication removes unwanted material to shape and finish a product to its desired design.

For this sophisticated operation, using the right grinding accessory can make all the difference in accuracy and efficiency.

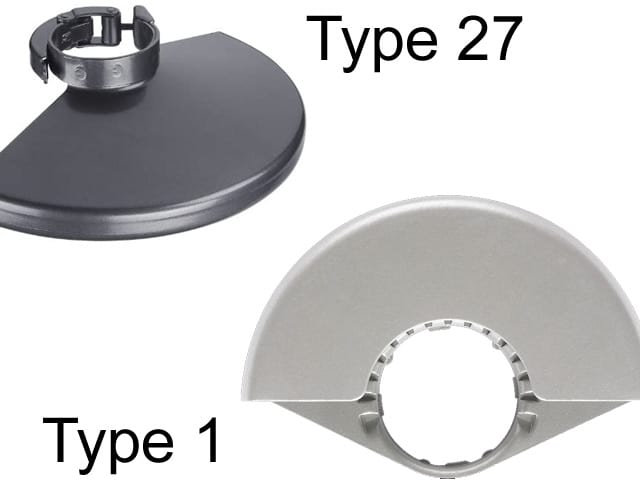

Two common types are Type 1 and Type 27 guard wheels, which differ by their surface texture when performing precision operations.

To better understand what sets these two types apart and how they complement different tasks, let’s look into their differences in cutting performance.

Type 1 Vs Type 27 Guard

Type 1 vs Type 27 guard is a tool to help protect your saw from damage and wear. These guards are different due to their guard.

The Type 1 Guard has an angle of 30 degrees, while the Type 27 Guard has an angle of 40 degrees. The main difference between these two guards is that Type 1 Guard is used for large power tools like circular saws. In contrast, Type 27 Guard is used for smaller hand-held portable power tools like drills or impact drivers.

Depending on the job, selecting the right safety guard is of utmost importance to guarantee the highest level of protection. Type 1 and Type 27 guards share many similarities, but a few key differences are worth noting. A Type 1 guard shields against sparks, molten metal, chips, and scale. In addition, it flattens grindings and helps maintain accuracy in longer runs.

On the other hand, a Type 27 guard is designed to perform light grinding or sanding tasks and offers more flexibility when working with curves or contours.

Both guards feature a depressed center for optimum safety. In addition, they can be tailored to fit most cup wheels, ensuring a comfortable grip during operation. Knowing the purpose of each type of guard can help save time, money, and effort. And more importantly, it provides optimal protection from potential workplace hazards related to angle grinding activities.

Type 1 Guard

It is for cutting and is designed to protect your hands from the risk of getting cut or injured using an angle grinder. The guard is easy to install and can be used with most angle grinders, including the Ridgid brand. It prevents accidental contact with the tool’s blade, which can lead to serious injury.

These guards are commonly found on table saws, but You can also use them on scroll saws and woodworking machines with a blade guard.

They’re designed to prevent kickback when the blade flies off the table and strikes something behind it, typically your hands. Kickback can result in severe injury or even death if you don’t wear proper safety gear.

Type 27 Guard

The type 27 guard is the most popular and widely used guard on table saws. It has a beveled edge, preventing kickback when cutting material.

This can be especially helpful if you have an aggressive blade or one that doesn’t follow your line of cut perfectly like some contractors’ blades.

Type 27 guard has anti-kickback pawl features. And built-in anti-kickback springs that prevent the blade from moving back toward you during use, so your hands remain safe.

What Is The Difference Between Type 1 And Type 27 Guards?

Type 1 vs Type 27 guard is two of the world’s most popular types of angle grinders. They have different features but offer high-quality cutting performance at a low price.

Type 1 angle grinders are made of stainless steel, while Type 27 angle grinders are made from carbon steel. Both materials offer durability and can withstand extreme temperatures without damage.

Type 1 angle grinders have a more robust design than Type 27 models, which makes them more durable and ideal for heavy-duty jobs like metal cutting and grinding concrete. They also have larger wheels and motors, which allow you to use more force when working with these machines than other types of angle grinders on the market today.

Type 27 angle grinders are designed to be compact and lightweight while offering all of the same features as their larger counterparts; they also cost less! In addition, the smaller size makes them easier to transport around your home or workplace, so you don’t have to worry about lugging around an unwieldy piece of equipment. Instead, whenever you need it, grab one from your garage or tool shed whenever you’re ready for some serious work!

Factors To Consider For Choosing Type 1 And Type 27 Guard

When you’re buying a type 1 or type 27 angle grinder guard, there are some things you should keep in mind. First, consider the safety of the tool. You must ensure that your guard will protect your hands, eyes, and ears from flying debris from using the tool.

The guard should be easy to use, whether type 1 or type 27. This includes choosing a guard that fits comfortably around your hand so that it doesn’t interfere with your grip on the tool itself.

Finally, think about how much noise level you want from your angle grinder. If lyou want a quieter model, check out our article on quietest angle grinders for more information about finding the right option for your situation!

Why Do You Need Type 1 And Type 27 Guards?

Type 1 and Type 27 angle grinders are extremely powerful tools that can quickly break down materials and make cuts. However, the main difference between these two angle grinders is that they have different guards. The guards that come with a Type 1 angle grinder are called type 1 guards and are designed to protect the operator’s hands from burns, cuts, and other injuries. By contrast, Type 27 guards are designed to protect against debris thrown off the machine by centrifugal force or any other chance event.

Conclusion

We hope that we’ve covered all the bases for you and that now you have a better idea of which guard will work best for your saw. So now go out there, get some wood and start cutting.

FAQs

What Type 1 blade provides?

The other name of the type 1 blade is type 41 cut-off wheels. This wheel is entirely flat, and it is best for general cutting. With this, you will get an additional cutting area that will reduce interference.

What are the uses of Type 27 grinding wheels?

They design it for rough grinding. You can grind on a range of materials, are type 27 grinding wheels. They are suitable for small workshops and the construction industry.

Which is the fastest grinding wheel?

Zirconia alumina is the fastest grinding wheel. It quickly cut the materials. It is made up of stainless steel, which is self-sharpened.